John Wolff's Web Museum

Rebuilding the Original-Odhner Model 239 Pinwheel Calculator

Contents

|

|

| Odhner 239 mechanism, 1960s |

Introduction

These notes give a detailed step-by-step procedure for a complete

disassembly and reassembly of the Original-Odhner Model 239 mechanical

calculator. They are also applicable, with suitable modifications, to

the other models in the 200 series, and in principle to any Odhner

machine from the 1920s to the 1970s.

The notes have been prepared and refined during the rebuilding of

a significant number of Odhner machines, and may provide a useful

guide to anyone faced with a similar task. The sequence of operations

described works well for me, but comes with no guarantees. No

responsibility will be taken for any consequences arising from the use

of these notes by others.

These notes are intended to be read in conjunction with two other

documents in this section:

Please study this material carefully before commencing your overhaul

and refer frequently as you proceed, especially to the illustrations

in the Technical Description.

If you use these notes to rebuild an Odhner I would appreciate

receiving your feedback, comments, or suggestions for improvement

via the enquiry form.

Disassembly

Please review the material in the

Notes on overhauling a mechanical

calculator before proceeding. It is suggested that you print a copy

of these notes, and tick off each step as it is completed. An Odhner

239 can be completely disassembled in an hour or two, provided that no

major problems are encountered.

- Carriage and covers

- Remove the carriage stop pin and its mounting plate (2 screws

through the large hole in the bottom cover).

- Hold down the carriage release tab and slide the carriage out to the

right-hand side. If the carriage fouls on the rotor or other mechanism,

leave it and continue.

- Remove the four screws and washers in the rubber feet and lift off

the bottom cover.

- Remove the four screws holding the side covers to the base. Slide

the covers downwards at the front, then forward, to disengage the

internal clips. The movement required is only about 1 or 2mm.

- Remove the winding handle stop plug and sleeve (2 special screws

from underneath) and remove the right-hand cover plate.

- Remove the top panel (2 screws each side), and the rear panel

(3 screws from underneath).

- Pull off the carriage shift buttons and remove the front panel

(3 screws from underneath).

- Main body

- Remove the rear panel and check dial mechanism (4 screws) and

disassemble (9 screws). Be very careful of the light springs under the

detent levers.

- Remove the rotor bearings from the side plates (3 screws each side).

- Lift the rotor from the left-hand end, disengage the right-hand

end, lift out and set aside.

- Remove 2 screws from underneath into each side plate. Ease the

plates up off their dowels, remove and set aside.

- Remove the interlock plate and bell assembly (3 screws).

- Remove the rotor interlock lever and pivot rod (2 screws underneath).

- Remove the 4 screws holding the carriage shift mechanism. Ease

the mechanism away from its dowel pins and disassemble.

- Left-hand side plate.

- Refer to the illustrations in the

Technical Description

and disassemble the counter reversing mechanism. When removing the

reversing body and gears (on the front shaft), be careful of the

tiny detent ball and spring inside the right-hand gear.

- If it is necessary to disassemble the reversing body, note that

the plain pin is staked at each end. Be careful of the tiny ball

and spring under the T-bar, and the larger spring under the

half-round pin.

- Right-hand side plate.

- Remove the spring, wire retainer, and circlip at the bottom front

and withdraw the sliding plate and shaft.

- If necessary (and if you have the facilities), drive out the tapered

pin and remove the main gear and drive shaft. Disassemble the non-return

pawl, spring, and wire ring.

- Disassemble the handle and locking pin.

- Carriage

- Pull off the back-transfer button and remove the carriage covers

(4 screws). Turn the clearing handles upwards to remove the end covers.

- Roll the carriage onto its back. Carefully loosen the two screws

holding the metal strip under the accumulator until the spring pressure

is released, then remove the strip and lift out the 12 carry lever detent

springs. Temporarily replace the strip to retain the detent pins. Roll

the carriage forward onto its base.

- Carefully loosen the three screws holding the right-hand end plate

until the spring pressure is released, then remove the screws.

- Working from the rear, observe that the sheet-metal frame of the

tens-carry mechanism behind the counter register is held in place by a

pin near the top of each side. The inner pin is formed on the end of

the accumulator star wheel shaft. Remove the screw and washer holding the

shaft to the centre pillar, then push the shaft outwards (to your left)

until it is clear of the carry mechanism. Remove the short pin

on the opposite side by pushing it fully out to the right. Lift the

interlock arn around the centre pillar, then lift out the carry

mechanism and set aside.

- Remove the back-transfer stop plate from the accumulator end pillar

(on your left).

- Continue pushing the accumulator star wheel shaft out to your left,

removing the bracket and spacers around the centre pillar, the star

wheels, and the back-transfer assembly.

- Remove the 4 screws and narrow retainer plates at the rear of the

accumulator register. Remove the two shafts, carry levers, support

arms, and spacers.

- Roll the carriage onto its back, remove the retainer strip again,

and push the carry lever detent pins out of their holes with a suitable

wire or tool. Be sure to recover all 12 pins. Note that there is no

detent on the bell lever in the 13th place.

- From the front, disconnect the spring from the back-transfer latch.

Fold the register retainers (each end) forward and clear of the

registers. Remove the bearing retainer plate and screw from the pillar

between the registers, then ease both register assemblies up and out

together.

- Disassemble the two registers, but keep them separate. Take careful

note of the sequence and orientation of the components as they are

removed from the shafts. The tapered pins in the clearing handles can

be driven out towards the front (if necessary), but take care to avoid

damage.

- Remove the screw and washer securing the detent lever shaft (at the

right of the centre pillar). Carefully push out the detent shaft and

remove the detent levers, balls, and springs. The balls are sometimes

held by a ring of dirt or oil at the top of the hole, and can spring

away unexpectedly when disturbed.

- Drive out the small rolled pin holding the arm at the outer end

of the back-transfer gear assembly and remove the gears and spacer.

- Counter carry mechanism

- From the rear, remove the circlip and long gear.

- Remove the circlip inside the inner end of the star wheel shaft,

then remove the shaft and star wheels.

- Lift and remove the carry levers.

- Ensure that the sliding collars are not stuck to their shaft.

Push out the shaft, leaving the collars and drive gear behind on the

toothed key strip. Remove and separate the components.

- Remove the spring plates and 7 detent balls (2 short screws from

underneath).

- Main rotor

- Withdraw the toothed locking bar and ring from the right-hand end.

- Remove the set screw in the round nut at the left-hand end of the

rotor discs. Wrap the rotor in a heavy cloth and hold it firmly, then

loosen the nut with a suitable C-spanner or a length of 4mm drill rod.

The nut will usually be very tight. Alternatively, grip the round nut

in a vice, tighten only as much as necessary, wrap a rag around the

rotor, grip firmly with both hands, and loosen the nut.

- Prepare a base for working on the pinwheel rotor by drilling a

10mm hole in a block of wood about 75 or 100mm square. Stand the rotor

shaft upright in the base.

- Note that the round nut is carried on a threaded collar which can

slide along the mainshaft. Unscrew the nut until it is level with the

end of the thread, then push it inwards. Push the inner gear and the

adjacent wide C ring inwards into the space created. Remove the split

C ring from between the two wide rings.

- Push the outer gear inwards and remove the split C ring from the

recess in its outer face.

- Remove the gears, then remove and disassemble the pinwheels one

at a time. Use plenty of solvent (and patience) if the wheels are

stuck to the shaft, and clean the residues from the shaft as each

disc is removed. Proceed very carefully to avoid damage to the

die-cast alloy. Withdraw the round alignment rod as soon as it comes

free. Be careful of the internal springs on the detent pawls.

- The driving gear assembly at the right-hand end is keyed to the

shaft and secured by another recessed C-ring. It is often stuck tight

with decayed oil. If removal proves difficult, leave it in place

rather than risking damage to the mainshaft.

Cleaning

Please review the general information about cleaning and checking

in the Notes on overhauling a

mechanical calculator, and proceed as described. Initial washing

and cleaning will take about 3 hours.

Reassembly

Please review the material on Reassembly in the

Notes on overhauling a mechanical

calculator.

Moving parts should be lubricated sparingly as they are assembled.

Apply a thin film of oil to steel parts with a (slightly) oily rag to

prevent rust, and apply a minimum of light oil to gears, pivots and

bearings. The pinwheels and setting rings should not be oiled.

In the notes following, screws listed as (eg) M3x8 are 3mm diameter,

standard pitch (0.5mm), and 8mm overall length. Tension springs listed

as (eg) 3x10x0.3 are 3mm diameter, 10mm closed coil length, and 0.3mm

wire diameter.

Final cleaning, checking, and re-assembly can be completed in about

4-6 hours if no major problems are encountered.

- Carriage shift mechanism

- Attach the 2 springs 3x4x0.26 from the shift pawls on the rear of

the large plate to the hole between.

- Place the long compression springs over the key stems. To make

assembly easier, compress the springs and temporarily tie them shut

with a piece of fine wire or string.

- Insert the key stems into their support bracket with the pins

facing rearwards.

- Place the support bracket onto the flat side of the larger plate.

Engage the pins with the slots in the two shift pawls behind, engage

the locating pins between the plates, and fasten with 2 screws M3x6.

- Attach the 4x8x0.3 spring to the flat end of the carriage release

arm so that it sits above the larger hole. Place the rubber washer

over the spring. If the washer is missing or damaged, cut a replacement

from 1.5mm neoprene sheet.

- Fit the carriage release arm to the rear of the assembly. Attach

the top of the spring so that it lies evenly between and parallel

to the keystems.

- Release the compression springs and check that the keys and the

carriage release arm move freely.

- Base plate

- Mount the interlock plate and bell assembly to the base with

3 screws M3x8.

- Locate the carriage shift mechanism on its dowel pins and attach

with 4 screws M3x8.

- Invert the baseplate and install the interlock lever between the

shift mechanism and the interlock plate on the bell assembly. Fasten

the short axle with 2 screws M3x12.

- Right-hand side plate

- Asemble the winding handle and locking pin.

- Assemble the drive gear and non-return pawl. Note that the pawl is

not symmetrical. Place it on the drive gear with the long pointed tooth

downwards and the side with the more equal spacing on the right. Then

fit the spring washer (bent side down) and the wire retaining ring.

- Fit the winding handle in its bearing. Fit the drive gear with

the long tooth of the non-return pawl facing the centre of the rotor

bearing housing and insert the tapered pin from the top. Check that

the long tooth swings (approximately) equal distances to either side

of the rotor bearing, then support the hub of the gear and drive in

the tapered pin.

- Check that the large pin at the top rear of the sliding interlock

plate is still firmly rivetted in place and correct as necessary. Fit

the shaft into the handle stop pillar and fit the circlip to the

locating pin at the bottom front. Fit the 4x7x0.4 spring from the

plate to the wire retainer (through the hole in the frame).

- Temporarily fit the rotor clearing sleeve, shaft extension piece,

and end plug to the handle stop pillar and secure with the two special

screws. Ensure that the assembly slides freely.

- Left-hand side plate

- Check the gears in the reversing mechanism for damage. The small

pressed-metal gears rivetted to the end plates may be badly worn, or

may have bent or broken teeth if the machine has been forced. Repair

as necessary.

- Place the die-cast side plate flat on the bench with the inner

face upwards.

- Stand the two 5x28 pillars in the rear holes in the side plate,

flanged ends down.

- Place the bright plate with two gears over the pillars with the

long arm facing upwards and forwards. Fasten with 2 screws M3x12,

1 M3x7, and 3 flat washers from outside.

- Assemble the reversing body. Check that the pointed T-bar

locates positively in its three detents, and that the spring-loaded

pin moves freely. Secure the plain pin in the original manner.

- Fit the tiny compression spring 2.2x5x0.5 and 3/32" ball into the

hole in the right-hand end of the reversing body shaft, then fit the

small gear with the cam side inwards and the notch over the ball.

Put on your safety glasses, insert a suitable tool (eg the back of a

knife blade) between the cam and the gear, press the ball down

into the hole, then push the gear fully home. The ball must rest in the

detent V-notch in the gear, and not in the gap between the gear and the

cam. When correctly fitted, the ball will be centred inside the gear

and clearly visible from the outside.

- Fit the larger cam and gear to the left-hand end of the reversing

body, then the large gear with the counter operating finger. The cam

and the operating finger both face towards the central body.

- Stand the large end of the assembly in the bearing in the

left-hand plate. Fit the slotted resetting arm into the small pivot

hole. Fit two long spacers over the pillars, then fit the top plate.

Insert the third pin and spacer at the front and fasten with 3 screws

M3x7 and flat washers.

- Attach the spring 2.8x4x0.3 to the rear of the resetting plate.

- Fit the side plate assembly to the base with 2 screws M4x14. Firm

up but do not fully tighten.

- Pinwheel rotor assembly

- Note that there is one pinwheel each numbered 1 (or 1a) and 6,

but two sets numbered 2 to 5. Each wheel in these sets has two numbers

(2-10, 3-9, etc) and two possible locations for the pairs of carry

pins. Use the numbers next to the installed carry pin. There are two

sets of setting rings numbered 1 to 5, which match the first number

on the pinwheel. The second No.1 ring goes on pinwheel 6.

- Fit the driving gear and flange assembly to the plain end of the

shaft, then fit the thick C ring into the single groove.

- Stand the shaft upright in your block of wood.

- Prepare pinwheel 1, setting ring 1, and pinwheel 2.

- Place pinwheel 1 onto the shaft. Fit the 9 pins, leaving them

slightly outside the edge of the wheel. Place the detent pawl and

spring into position, but do not compress the spring. Place the

setting ring over the wheel, engage the pins with the slot, engage

the hub, then press the detent pawl into position against its spring.

Hold the setting ring and immediately fit pinwheel 2 to keep the

assembly together.

- Hold down pinwheel 2 and check that the setting ring rotates

easily. The ring may catch on the first couple of moves as dust gets

pushed aside. If problems persist, look for nicks or damage to the

discs or rings, or try reversing the offending pin.

- When the operation is correct, continue in the same manner

to disc 11 and carry sectors 12 and 13.

- Check that the two rows of carry pins progress uniformly across

the rotor, then fit the alignment rod into the holes.

- Fit the end disc with the concave side out.

- Repair the threads on the inner collar where they have been

damaged by the set screw. Fit the round nut so that the shouldered end

of the collar and the set screw hole in the nut are both towards the

outside.

- Place the collar assembly, small gear, two wide C rings, and large

gear onto the shaft.

- Fit the first split C ring into the outermost groove on the shaft.

Slide the large gear outwards so that the split ring is held in the

recess in its outer face. Fit the second split ring between the two

wide rings. Firm up the round nut.

- Drop the rotor and wood block firmly onto the bench to settle

the discs, then tighten the round nut. Repeat several times until

fully tightened.

- Operate all the setting rings through their full stroke. The rings

should move evenly over the detents in both directions, with no sign

of stiffness or sticking. Correct as necessary. When all is well,

re-tighten the round nut and tighten the set screw.

- Fit the toothed locking bar and ring from the driving end. Check

that it has no effect when fully inserted, but locks the setting rings

when withdrawn 2-3mm.

- Pinwheel rotor installation

- Check that the two rotor bearings can be inserted easily into

their mountings. Ease any scrapes or nicks around the bearing, or

around the housings in the side plates. The shorter bearing goes

on the right-hand side. Remove the bearings.

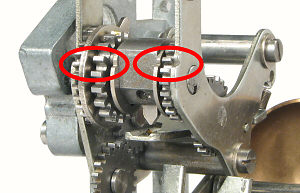

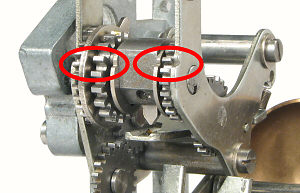

Check that the right-hand gear in the counter reversing assembly is

still in its detent position. Rotate the gears so that the timing

marks on their cams (adjacent to the central body) align with the

V-notches in the fronts of the sub-frame plates (see illustration

opposite).

Check that the right-hand gear in the counter reversing assembly is

still in its detent position. Rotate the gears so that the timing

marks on their cams (adjacent to the central body) align with the

V-notches in the fronts of the sub-frame plates (see illustration

opposite).

- Set the handle in its stop and the rotor setting rings to zero

(fully rearward).

- Hold the rotor with the setting levers one place rearward of

top. Assemble the right-hand side plate to the rotor so that the rotor

locking ring engages with the large pin at the top rear of the sliding

interlock plate.

- Hold the rotor and side plate together and insert the free end

of the rotor shaft into the left-hand bearing housing (no bearings

yet). Lower the right-hand side plate onto its dowels and fasten with

2 screws M4x14. Firm up but do not tighten fully.

- Lift the rotor clear of the driving gear and turn it until the

interlock plate on the bell assembly can be lifted into the notch

in the rotor end disc. Engage the driving gears and insert the right-hand

bearing.

- Engage the gears on the left-hand side. Check the timing marks,

correct as necessary, then insert the bearing.

- Fit the bearing covers and fasten temporarily with 1 screw M3x8

each side.

Adjust the end stops to roughly align the gears. Final adjustment

will be made after the carriage is installed.

- Check the reversing operation. Carefully make a forward turn and

watch as the counter drive pawl passes through the cut-out in the

rotor shaft. The pawl will foul on the shaft if the assembly is

incorrect, and may cause damage if turned vigorously. At the end of

the turn, check that the T-bar has moved to the left, and the timing

marks have returned to their aligned positions. Lift the rotor

interlock plate and check that it resets the T-bar to the centre

position. Repeat for a backward turn (in which the T-bar moves to

the right). Remove the rotor bearing and re-set the gear engagement

if necessary.

- When all is correct, fit the remaining 4 screws M3x8 to the

bearing cover plates.

- Rear panel and check dial

- Check that all the detent pawls are free to move. Carefully fit

the springs into their holes and fold the detents over.

- Fit the narrow star wheels onto their shaft and attach with 2

screws M3x10.

- Fit the numeral wheels onto their shaft with the flat washer at the

left. Replace any shims on the right. Fasten with 2 screws M3x12.

- Assemble the wide star wheels and the long shaft onto the slotted

locating plate and fasten with 2 screws M3x8. Check that the wheels

turn freely.

- Place the wide star wheel assembly in position, fasten the retainer

strips with 2 screws M3x8, and fit the shouldered screw at the bottom

left. Check that the plate slides freely between the two stops.

- Slide the plate to the left and turn the check dials downwards

until they stop at zero.

- Place the handle in its stop and the setting rings at zero.

- Working from the rear, place the panel in position on its dowels.

Look through the rectangular cutout and engage the notch in the

sliding plate with the tab on the handle interlock plate. Fasten with

4 screws M3x8.

- From underneath, tighten the four M4 screws into the side plates.

- Check that the dial operates correctly. If the setting rings are

locked, push the locking bar slightly inwards to release them. (The

locking mechanism will be adjusted until after the rotor has been

aligned with the carriage).

- Carriage preliminaries

- The die-casting alloy can move slightly with time, so it is

advisable to check the carriage alignments first to avoid difficulties

during assembly. Proceed as follows:

- Insert the empty carriage into the base and check that it moves

smoothly from end to end. Stiff spots will leave tell-tale marks on

the bearing surfaces, which can be eased with a fine file or scraper.

- Fit the carriage positioning rack (teeth down) at the front of

the counter register and fasten with 2 screws M3x8. Check that the

shift controls operate correctly.

- Check the fit of the three register shaft bearings in their

housings. Remove any nicks, scrapes, or spurious die-cast metal to

ensure a smooth fit.

- Check that the detent shaft is straight, and that it can be

inserted smoothly into place at the front of the carriage. Correct

as necessary.

- From the rear, fit the lower 4x70mm shaft, the two star wheel

support arms, and the two spacer washers at the right of the arms.

Note that the spacer washers are filed flat on the bottom.

- Feed in the upper 4x93mm shaft from the outer end. If the shaft

is tight, ease the holes or file the supporting surface until the

fit is smooth but not loose.

- Temorarily fit the 4 shaft retainers and screws M3x8.

- Check that the star wheel shaft is straight. Check that it passes

smoothly through the outer pillar and the intermediate supports, and

seats properly in the centre pillar. Adjust as necessary.

- When all alignments are correct, loosen the 4 retainers and remove

the upper shaft.

- Carriage registers

- If the counter clearing handle has been removed, place the bearing

over the shaft, fit the spring into the hollow end, then the narrow

flat washer. Place the handle in position, align the holes, compress

the spring, and insert the tapered pin from the front. Looking from

the outer end with the handle in its normal position, the clearing

teeth should face towards 7 o'clock.

- Fit the pressed-metal cup over the cam and pin, then fit the

shim washer and numeral wheels.

- Fit the interlock cam with the cam facing the end of the shaft.

- If the accumulator clearing handle has been removed, place the

large flat washer over the shaft, followed by the spring, sleeve,

thin flat washer, and the carriage end plate. Place the handle in

position, align the holes and insert the tapered pin from the front.

Looking from the outer end with the handle in its normal position,

the clearing teeth should face towards 1 o'clock.

- Fit the back-transfer operating lever, forked lifting lever and

wire retainer to the accumulator bearing and place onto the shaft.

- Fit the back-transfer release cam with its smaller hub inside the

shaft bearing.

- Fit the numeral wheels, then the interlock cam with the cam

facing the end of the shaft.

- Place the compression springs and detent balls into their holes

in the carriage frame. Note that the counter detents have shorter

springs.

- Feed in the detent lever shaft from the right-hand side. Fit the

register retainer arm (big end down), back-transfer latch, accumulator

detents (short arm vertical at the front), counter detents, and the

left-hand retainer arm. Secure the shaft with 1 screw M3x7 and flat

washer at the right of the centre pillar.

- Open the two bearing retainers, and pull the back-transfer latch

forward.

- Check that both register clearing pins are in their normal

positions (at the bottoms of their cams).

- Fit both register shafts into the centre bearing (groove to right).

Align the end bearings with their curved faces uppermost and place the

assembly above the three pillars.

- Attach the 4x7x0.6 spring between the back-transfer lifting arm

and the latch lever at the front. Ease the register assembly down into

the carriage frame, keeping the back-transfer arms pointing upwards

and the latch forward.

- Close the outer bearing retainers, fit the centre retainer

(1 screw M3x8), and attach the right-hand end plate (3 screws M3x8).

- Turn all the dials by hand and check the detent and clearing

operations.

- Check that the back-transfer control raises, latches, and releases

the lifting arm.

- Engage the back-transfer, rotate the accumulator clearing handle,

and check that the lifting arm drops just before the end of the turn.

- Accumulator carry mechanism

- Working from the rear, feed in the upper 4x93mm shaft from the handle

end and fit the carry levers. The bell lever (with the extra tail) goes

last, next to the centre pillar. Tighten the 4 retainer plates, then check

that the carry levers all move freely.

- Assemble the wide back-transfer gears onto their shaft, hubs first,

then the 3.5mm spacer. Fit the outer arm, align the holes, and press

in the rolled pin. Place the assembly in position behind the register,

with the end of the shaft engaged with the fork in the lifting arm.

- Feed in the star wheel shaft through the end pillar, then through

the register retainer arm and back-transfer arm. Some machines have

spacers on one or both sides of the back-transfer arm, while others have

them as part of the arm.

- Install the star wheels and feed in the shaft to retain. Continue

through the inner back-transfer arm, 3.5mm spacer, and the interlock

arm around centre pillar.

- Fit the 0.5mm shim washer (if present) between the centre pillar

and the counter side of the interlock arm.

- Fit the M3x7 screw and flat washer into the rear of centre pillar

to hold the accumulator star wheel shaft, but do not tighten.

- Check that the register dials and carry levers all move freely.

It may be necessary to remove the star wheels and ease the intermediate

supports sideways to equalise the clearances along the shaft. The bell

lever in particular must be completely free.

- Fit the back-transfer stop to the rear of the handle-end pillar

with 2 screws M3x7. Check that the back-transfer gears rise, latch,

and reset correctly.

- Roll the carriage onto its back and drop in the carry lever

detent pins. The wedge at the bottom of the pins must be aligned

horizontally, ie, along the carriage axis. Insert the springs and fit

the retainer strip with 2 screws M3x7.

- Check that the carry lever detents all operate smoothly. Note that

there is no detent on the bell lever.

- Place a straightedge across the carriage base and check that the

edges of the 2 screw heads do not extend beyond the level of the base.

File the screw heads if necessary to ensure that they do not scrape on

the bearing surfaces in the machine base. (You may find 2 of the screws

with heads already chamfered).

- Counter carry mechanism

Find the sliding collar with the operating fingers closest

together. Place it on the bench with the keyway at 10 o'clock and the

fingers pointing downwards. Line up the remaining six collars to the

right with the keyways in the same position and the fingers at gradually

increasing angles. The fingers on the rightmost collar will be facing

slightly upwards.

Find the sliding collar with the operating fingers closest

together. Place it on the bench with the keyway at 10 o'clock and the

fingers pointing downwards. Line up the remaining six collars to the

right with the keyways in the same position and the fingers at gradually

increasing angles. The fingers on the rightmost collar will be facing

slightly upwards.

- Hold the key strip with the teeth upwards and the wide tooth (with

the hole) on your right. Place the drive gear immediately to the left of

the wide tooth, with its hub to the left and its keyway engaged with the

next tooth.

- Add the collars in order (right to left) with the fingers on the

right and the keyways engaged with the teeth on the key strip.

- Working from the rear of the carry frame (long arms facing away), put

the collar assembly in position (small end first) with the gear resting

in the slot in the base.

- Insert the plain end of the shaft from your left-hand side, and

assist the collars onto the shaft. The last two teeth on the key strip

are positioned on each side of the right-hand frame. Be careful handling

the assembly prior to installation as the shaft can easily fall out.

- Push the collars to the left and check that both rows of fingers are

aligned at uniformly increasing angles.

- From the front, hold each carry lever with the long end up and the

open side away. Pass the long end up through the slot in the top plate,

fit the open side into the V-groove in the collar, then drop the bottom

end into the slot in the base.

- From the rear, start the plain end of the star wheel shaft from your

left-hand side. Fit the 1.8mm spacer, the star wheels with their hubs

to right, and the 8.5mm spacer at the right. Fit the circlip at the

inside of the left-hand side.

- Fit the long gear and circlip.

- Invert the frame and fit the seven 3/32" detent balls, two spring

plates, flat strip, and 2 short screws M3x4.

- Check that the carry levers move and latch correctly. Rotate the long

gear as necessary to allow the operating fingers to engage with the star

wheels. (The engagement will be synchronised through the gearing when the

carriage is installed).

- From the rear of the carriage, push back the accumulator star wheel

shaft until it is clear of the counter side. Check that the curved

counter register retainer arm is in position against the end pillar.

Lift the central interlock arm and insert the carry mechanism.

Hook the long forward arms over the detent shaft at the front.

- Push the accumulator star wheel shaft inwards to engage with the

hole at the top of the carry assembly, then insert the shouldered pin

from the other side. Tighten the retaining screw on the star wheel shaft.

- Installing the carriage

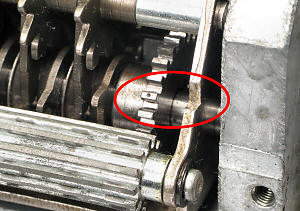

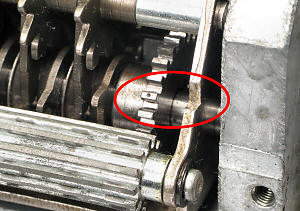

Examine the narrow gear at the outer end of the counter carry

mechanism and locate the tooth marked with a dot on its tip. Align

this dot with the V mark on the adjacent frame (as illustrated).

Examine the narrow gear at the outer end of the counter carry

mechanism and locate the tooth marked with a dot on its tip. Align

this dot with the V mark on the adjacent frame (as illustrated).

- Support the front edge of the machine on a small block so that the

rotor interlock lever (under the left-hand side) is clear of the bench.

- Set the winding handle in its stop and the two clearing handles in

their home positions.

- Lift the back-transfer interlock arm (under the front right-hand

side of the rotor) to its upper position.

- Slide the carriage in from the right-hand side until it stops

against the shift mechanism. Press the carriage release lever and

continue carefully. Look in horizontally from the left-hand side and

assist the long gear in the carriage to engage with the driving gear

in the main body. Release the carriage release lever and push the

carriage further until it locks. Check the alignment marks again and

repeat the installation until correct.

- Temporarily fit the carriage stop pin (under).

- Final adjustments

- Support the front edge of the machine on a small block so that the

rotor interlock lever (under the left-hand side) is clear of the bench.

- Check the operation of the carriage shift mechanism, and ensure

that the carriage is held securely in each position. Set the carriage

fully to the left.

- Set the first and last rotor discs to 9 and turn the handle carefully.

Check that the extended pins on the rotor are properly aligned with

the accumulator star wheels, and that the counter drive pawl is centred

over the corresponding counter star wheel. Adjust the bearing end stops

to provide the best alignment with minimal end play, then tighten the

lock nuts.

- Temporarily place the top cover in position and check that the

setting rings do not rub on the sides of their slots. Repair any bent

or damaged slots, and re-adjust the rotor position if necessary. Remove

the top cover when satisfactory.

- Set the rotor to zero and the carriage fully to the left. Give the

winding handle one forward turn and observe that the T-bar in the

counter reversing body has moved to the left. Slowly rotate the counter

clearing handle and watch the movement of the slotted resetting arm under

the reversing body. Note whether the arm rises far enough to reset the

pointed T-bar to its central position.

- Operate the accumulator clearing handle and note whether the

interlock plate rises far enough to prevent the rotor turning during

clearing, but not so far as to bring the resetting arm into contact

with the T-bar.

- These movements are frequently inadequate, due to wear on the cam

follower (ie, the interlock arm around the central pillar on the

carriage). Correct by extending the appropriate vertical finger on the

interlock plate, or building up the operating surface of the interlock

arm. A suitable piece of steel or brass can be soldered, brazed, or

screwed into position, then filed down to suit. If repairs have been

made, repeat the previous two tests to ensure satisfactory operation.

- Set the rotor to zero and the carriage fully to the left. Give the

winding handle one forward turn to set the counter direction, then one

backward turn to return the count to zero. Very carefully make a second

backward turn, and observer the progress of the secondary carries

("ripple carry") as the register changes to all 9s. Make a forward turn

and watch as the register returns to zero. The operation should proceed

smoothly and easily in both directions. Problems are most likely due to

incorrect timing when installing the carriage, or excessive wear in

the gears in the reversing mechanism.

- Check that the setting rings are locked when the handle is pulled

outwards, and that they become free when the handle is in its stop.

Correct as necessary to obtain prompt and reliable operation.

- Check the operation of the rotor quick-clearing mechanism. Hold the

button on the handle stop pillar inwards with your thumb, pull out the

handle, and turn forwards until it stops (about 1/4 turn). Return the

handle to its stop. It may be necessary to adjust the lateral position

of the sliding gear assembly on the rear panel by bending the

interlocking tabs.

- Clear the setting rings using the quick-clearing mechanism. Set the

carriage to its leftmost position and check that the back-transfer gears

rise and latch correctly. Adjust the back-transfer stop and the latch

lever if necessary to obtain full engagement without binding.

- Check the operation of the back-transfer interlock. Give the handle

a forward turn, then check that the back-transfer lever can not be

engaged. Reset the interlock by using the quick-clearing mechanism,

then check that the back-transfer gearset rises, latches, and releases

correctly. The interlock is operated by an arm attached to the handle

interlock plate (under the right-hand end of the rotor), which may be

bent as a result of forcing or incorrect removal of the carriage.

Correct as necessary.

- Check that the left-hand arm of the back-transfer gear assembly

does not foul on the rotor end plate. Adjust if necessary.

- Set the carriage to the left. Set a 1 in the first rotor position,

crank forwards and backwards, and check that ripple carries operate

smoothly in both directions on both registers.

- Verify all operations with suitable test calculations.

- Finishing off

- Assemble the perspex windows and decimal indicators in the covers.

- Remove the carriage and install its covers with 4 trim screws M3x8.

- Fit the back, front, and top covers (in that order) to the main

body. Replace the carriage shift buttons and back-transfer button.

- Remove the handle stop plug and clearing sleeve. Fit the side

covers, sliding them rearwards then upwards to engage the internal

clips. Tighten the clips first if necessary. Fasten with 4 screws

M3x7. Replace the clearing sleeve and handle stop plug.

- Reinstall the carriage, paying attention to the counter carry

timing. From underneath, re-fit the carriage stop pin, and check

that the carriage locks securely at each end of its travel. Rotate

the stop pin or adjust the eccentric if necessary.

- Fit the bottom cover and rubber feet. Satisfactory replacement feet

can be cut from 4.5mm neoprene sheet with a 30 or 35mm (1.5") wad punch.

Original text and images Copyright © John Wolff 2009-20.

Use at own risk; beware of errors; suggestions for improvement welcome.

Last Updated: 15 September 2020 - many minor changes and clarifications.

Back to: Home

Calculating Machines

Pinwheel calculators

Original-Odhner

Odhner mechanism

Tech Index

Check that the right-hand gear in the counter reversing assembly is

still in its detent position. Rotate the gears so that the timing

marks on their cams (adjacent to the central body) align with the

V-notches in the fronts of the sub-frame plates (see illustration

opposite).

Check that the right-hand gear in the counter reversing assembly is

still in its detent position. Rotate the gears so that the timing

marks on their cams (adjacent to the central body) align with the

V-notches in the fronts of the sub-frame plates (see illustration

opposite).

Examine the narrow gear at the outer end of the counter carry

mechanism and locate the tooth marked with a dot on its tip. Align

this dot with the V mark on the adjacent frame (as illustrated).

Examine the narrow gear at the outer end of the counter carry

mechanism and locate the tooth marked with a dot on its tip. Align

this dot with the V mark on the adjacent frame (as illustrated).